Product

Domestic Sewage Treatment in Chennai

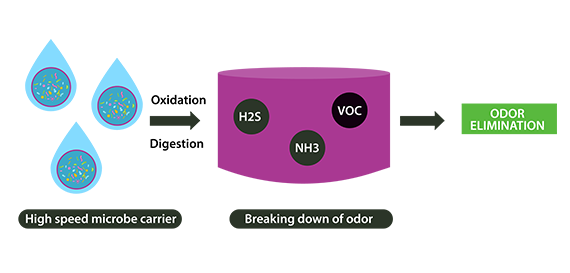

Working Principle

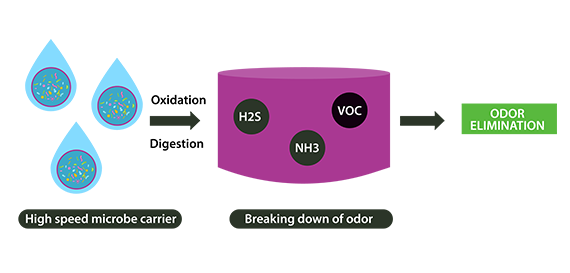

Application

Odor Solution

-

StinkKill BXGE-0301 is a bio-organic natural odour control agent, which is easy to use, effective and economical.

-

It is an Odour eliminator and NOT a masking agent.

-

Can be used for odor control in various segments of Industries.

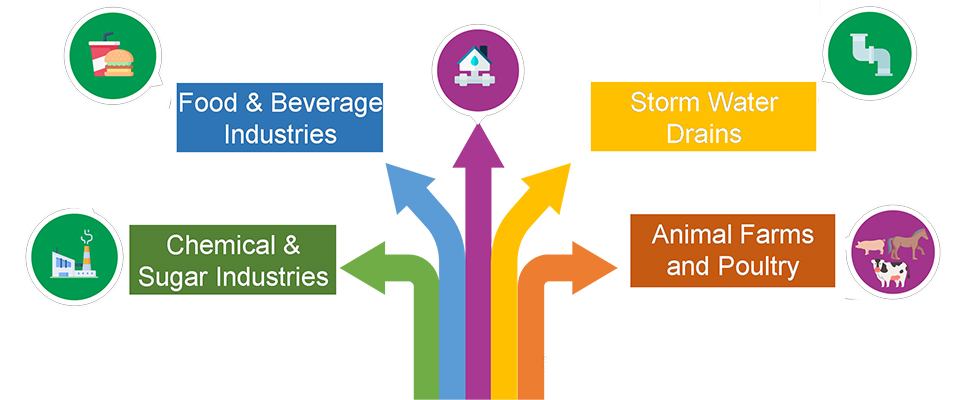

Bioxgreen O&MPlus Solutions for STP, ETP & CETPs

O&M of the Plant

-

Study and assess the existing condition of the plant and carry out due diligence

-

Submit Proposal for comprehensive O&M of the Plant

-

Carryout O&M for the specified period of the contract

Bioremediation

-

Test the effluent characteristics and carryout baseline studies

-

Installation of Physical Infrastructure & Dosing Stations, as required

-

Carryout Dosing of Bioxrem (Bio-culture) as per SOP

-

Achievement of Performance Targets conforming to contract agreement.

Odour Control

-

Carryout Ambient Air Quality Analysis

-

Deploy Odour elimination product - Stinkill

Reduce Foaming

-

Carryout tests for causative factor for Foaming

-

Deploy Bioxrem conforming to dosing protocol

Benefits

Who are we?

Bioxgreen Technology Pvt Ltd (BXG) is biotechnology company that provides niche and innovative solutions for wastewater management in the Municipal and Industrial segments. BXG has been pioneering pilot studies and proof of concepts for addressing the challenges of wastewater treatment both in greenfield and brownfield projects. Through the R&D facilities at Hosur in Tamilnadu, BXG has engineered innovative products & solutions for contemporary STPs, ETPs, Drains / Nallahs towards mitigating the ever-increasing contamination issues that plague the brownfield installations.

What do we offer in brownfield wastewater management?

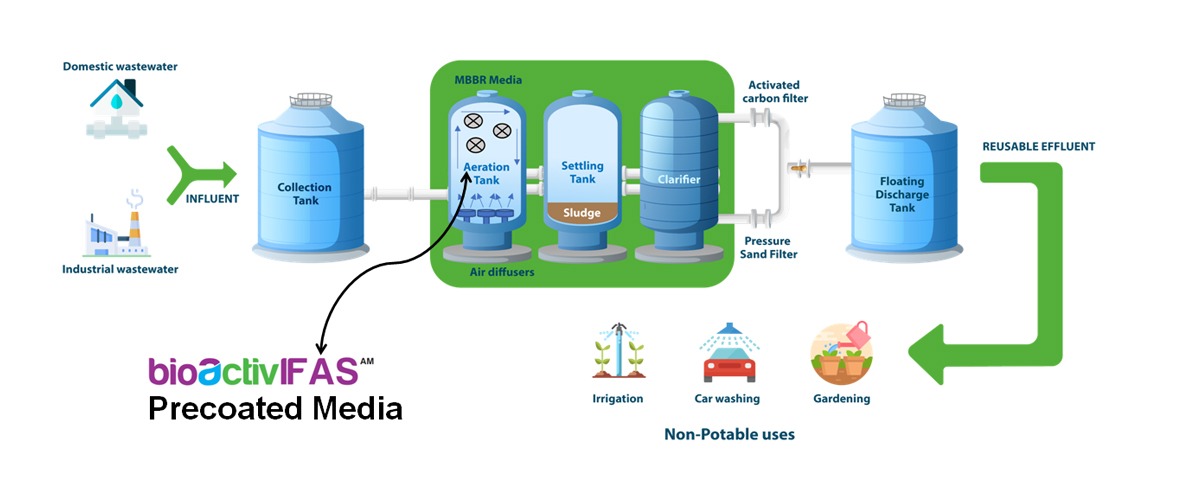

To alleviate the problems of achieving the stringent regulatory standards, BXG hasdeveloped customised end-to-end solutions to upgrade under-performing brownfield ASP wastewater treatment plant.To achieve the desired discharge water quality, we have leveraged on BioActivIFASAM which is based on innovative attached growth technology. As manufacturers of bespoke microbial consortia, BXG’s pre-coated BioActiv IFASAM is distinctly different from other IFAS solutions. It has the advantage of an enhanced surface area that is pre-coated with active bio-culture facilitating seamless integration for biological treatment of wastewater!Our solutions are innovative, efficient, reliable, sustainable and customised to suit the requirements of wastewater treatment, targeting ‘on-the-ground’ O&M challenges of effluent quality discharge.

How is BioActiv IFASAM different from conventional IFAS?

- BioActivIFASAM is pre-coated with pollutant specific pure culture microbial consortia manufactured by Bioxgreen.

- Has larger surface area as compared to conventional IFAS.

- Facilitatesshorter start-up and activation time for reaction kinetics of microbes in the system.

- Provides efficient and robust solution depending on wastewater characteristics, while achieving the target discharge norms.

- Bespoke consortia is based on the unique principle of RGRC™ (Rapid Growth Robust Consortia) bio-culture that works in synergy with the existing natural strains present in wastewater.

- Can be incorporated in existing wastewater treatment plants thus upgrading and improving the process efficiency of treatment facilities.

How does BioActiv IFASAM work?

The working principle involves a three-pronged approach encompassing:

Research

-

Proper diagnosis of existing system and treatment design.

-

Analysis of the effluent characteristics to identify major reasons of pollution.

-

Establishing the Baseline values of the effluent inlet and outlet characteristics in the existing systems.

-

Calculate and confirm the air requirement of the current facility.

Innovation

-

Our think-tanks in R&D along with Microbiologists have over the years assimilated the capability to develop Bespoke pure culture based microbial consortia for various effluent characteristics.

-

These cultures are pre-coated on Biomass media in BXG’s facility and deployed at project sites for application in WWT plant.

Execution

-

At site, “BioActiv” IFASAM pre-coated Biomass media is deployed in the existing aeration basin.

-

The first step is introduction of Initial booster dose of bio-culture along with pre-coated media.

-

This is followed by a maintenance dosage post stabilization of the system and achieving of the desired results.

Key Differentiators

-

BioActiv’ IFASAM can be custom designed for Industrial ETPs ensuring the pollutant under check is effectively biodegraded.

-

‘BioActiv’ IFASAM operational activities are easy to perform and could be managed by any trained and skilled operator.

-

‘BioActiv” IFASAM carries out better nitrification compared to simple suspended growth systems.

-

‘BioActiv’ IFASAM can handle shock loads with quick upset recovery and shall not disrupt the output parameters.

-

Double the efficiency as compared to the conventional IFAS systems available in market, where cow dung / sludge based consortia are commonly used.

-

The fixed biomass combines aerobic, anaerobic & anoxic zones and increases the Biomass Retention Time.

-

Quick reaction time thereby stabilizing the system in a shorter period.

-

Instant activation of consortium due to presence of a pre-formed biofilm of customized high potency, high efficient bio-culture on the surface of the Media.

-

Fixed Biofilm of Pollutant specific pure culture consortium of microbes remains resident in the reaction mass (Aeration Tank) to carry out the biodegradation activities.

Fact Sheet

| BioActiv IFASAMpre-coated media | Conventional media |

|---|---|

| > 580 m2/m3 surface area (10,000 pc) | 380 m2/m3 surface area (10,000 pc) |

| Specific Gravity 1.01 (sinks in water) | Specific Gravity < 0.98 (floats in water) |

| No. of pieces per m3 – 7,500 – 11,000 approx. | No. of pieces per m3 – 70,000 approximately |

| Oval shaped media | OD – 25mm |

| MOC – Thermosetting resin – density – 1.35 kg/m3 | MOC – PP/HDPE – density – 0.7 to 0.93 kg/m3 |

| Media sinks in water – 100 % wetted surface | Reduce wet surface caused by floating |

| 7% to 10% of liquid volume of aeration tank | 30% to 50% of liquid volume of aeration tank |

| Maximum temperature – 55° C | May clog with prolonged running |

| Avoid sludge recirculation | Sludge recirculation necessary |

| Hydrocarbon resistance – very good | Higher transportation cost |

| Non-clogging | Higher investment due to more media for same application |

| Non degradable MOC | |

| Lower transportation cost and investment |

A brownfield ASP wastewater treatment plant that is currently undersized or working inefficiently can be upgraded using any standard IFAS technology. IFAS technology is well known to introduce attached growth process into an existing ASP.

But, what if you had an IFAS technology with bespoke consortia of active bio-culture that is “plug and play” at the same time achieving guaranteed results.

Bioxgreen’s “BioActive” IFAS uniqueness is the fact that the Media is pre-coated with native high potency and high efficiency pure culture based microbial consortium.

Bioxgreen’s Pre-coated Media has a biofilm formed on the surface of the Media which gets instantly activated on coming in contact with the waste water. This system can be retro-fitted to existing wastewater treatment plants thus upgrading and improving the process efficiency of existing treatment facilities or newly constructed treatment facilities.

BioActive’s bespoke consortia involves the unique principle of RGRC™ (Rapid Growth Robust Consortia) bio culture that works in synergy with the existing natural strains present in the effluent.

"BioActive" IFAS stabilizes in half the time as compared to the existing IFAS systems and is guaranteed to achieve the desired outlet parameters.

BioActive’s RGRC™ is two times more efficient than the commonly used Cow dung consortia.

-

pH 6.5-7.5

-

BOD < 10 mg/ L

-

COD < 50 mg/ L

-

TSS < 20 mg/ L

“BioActive” IFAS

What is "BioActive IFAS" process?

-

Test and establish the baseline of the current effluent inlet and outlet characteristics

-

Understand the present flow through put into the wastewater treatment facility

-

Calculate and confirm the air requirement of the current facility

-

Bioxgreen will prepare a bespoke consortia for the particular effluent

-

Bioxgreen will coat the IFAS media in their facility and will tender the culture dormant prior to shipping

-

Bioxgreen may suggest certain changes to the existing facility (maynot be required in most cases)

-

Once at site, IFAS will be deployed in the current aeration basin.

-

An initial booster dose would be recommended initially and later a fraction of the booster dose would be recommended as maintenance dose post stabilization of the system and meeting the desired objective.

Advantages:

-

The fixed biomass combines aerobic, anaerobic and anoxic zones and increases the Biomass Retention Time.

-

BioActiv IFAS is custom designed for Industrial ETPs ensuring the pollutant under check is effectively biodegraded and mineralized within the short Retention time

-

BioActiv IFAS carries out better nitrification compared to simple suspended growth systems. System nitrification is also restored at a faster pace owing to large mass of nitrifiers getting retained on the Bio-film

-

Can handle shock loads with quick upset recovery and shall not disrupt the output parameters

-

Stabilises plants in half the time taken for regular IFAS

-

Improved process stability

Fostering nature-based solutions for clean &

green

frontiers

in waste management

Chennai Office:

Ghatala Towers, 3rd Floor,

19 Avenue Road,

Nungambakkam,

Chennai – 600034

Landline: 044 79683723

www.bioxgreen.com

Mumbai Office:

B-21, Ground Floor,GundechaOnclave,

Kherani Road, Saki Naka,

Next to Post Office,

Andheri (E), Mumbai – 400072

Landline: 022 66990006

.png)